A mobile robot will revolutionize the construction industry. “The Next Generation Builder Is Coming”

There is no turning back from robotics – argue labor market experts. In their opinion, robots in many companies are a modern solution that also allows filling numerous and previously unfilled vacancies. Robots will revolutionize further industries. Their prototypes have already appeared in trade and on construction sites.

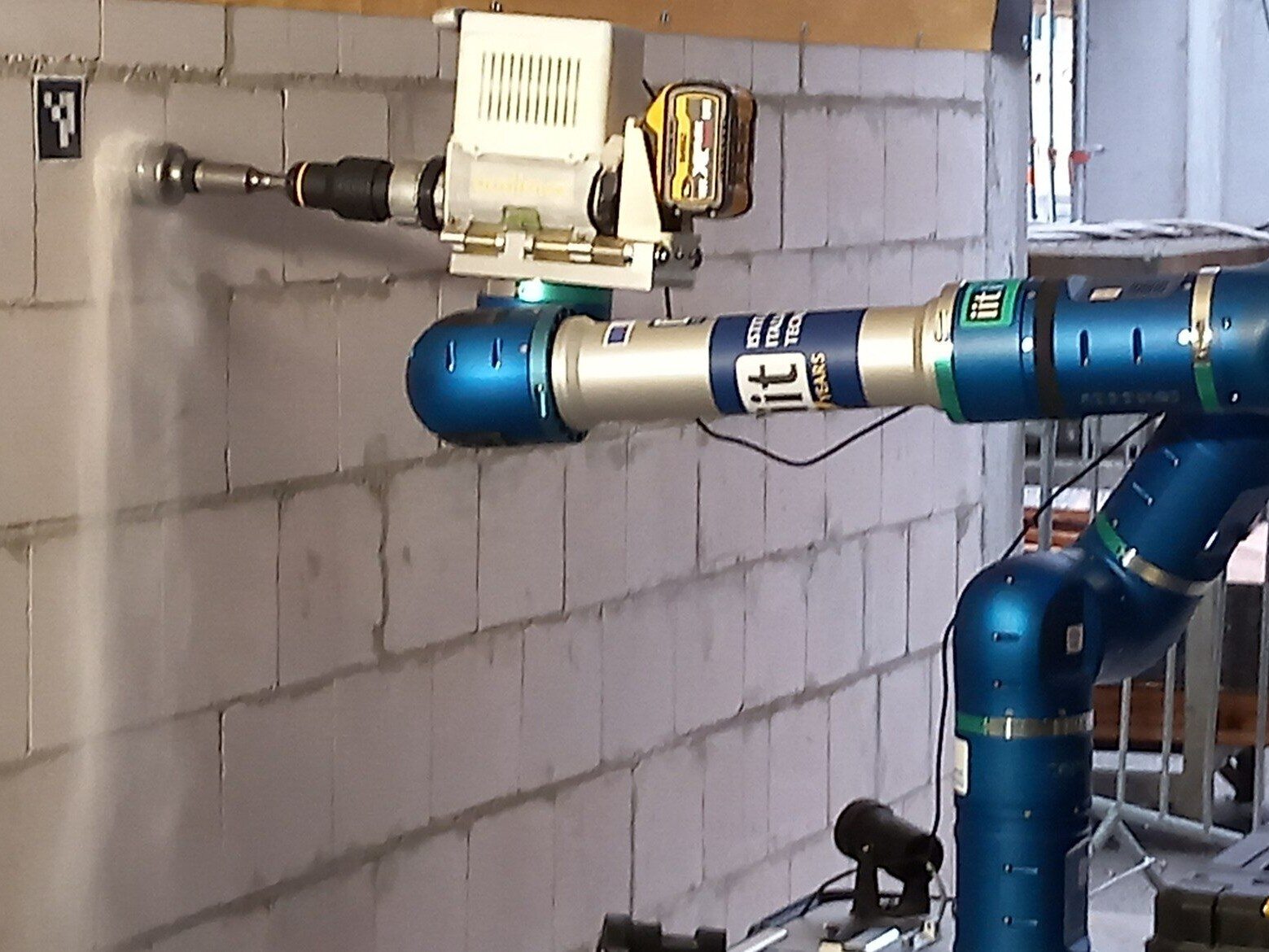

Over the weekend, a mobile robot started working in one of Krakow’s investments. The machine helps move heavy elements, drills holes in walls, paints rooms and sprays floor insulation. – This robot will support, but will not replace, a human. I can say this with full responsibility. Construction works using this equipment will be “Next Generation” construction – says a representative of Budimex.

Dariusz Brzostek, Wprost.pl: Where did the idea for the design and construction of the robot come from?

Marek Klusek, director of the guarantee, innovation and contract conditions department of Budimex: Out of necessity. First of all, we have fewer and fewer workers on construction sites, and we constantly need workers. Secondly, our society is aging, and since we are socially sensitive, we want to have both security. The idea is to support a human on a construction site who cooperates with a robot. The machine will help workers carry heavy objects, and if necessary, it will replace people on the construction site at night, performing monotonous work, such as drilling holes in walls. Thanks to this, it will prepare the work front for the next day so that employees can continue further work.

What can the robot already do? What are his main tasks on the construction site?

The machine can drill holes in the wall. He is excellent at moving heavy objects together with another employee. He carries a load weighing 20 kilograms on his shoulder, and the employee supports the same amount. The robot can also paint rooms or spray floor insulation. His skills have so far been tested in the laboratory.

Now he is undergoing a worker’s baptism on the battlefield, on our construction site, in real conditions, where there is a lot of dust and changeable surroundings. He will work in these target conditions every day, so we want to make sure that he will fulfill this entrusted task. The robot is based on optical sensors, cameras and lidar. We are testing how it copes in such conditions and so far, it is doing quite well.

What plans does the company have for the robot after completing tests on the construction site?

There will certainly be a continuation, i.e. the development of his skills, optimization of the speed of operation and the entire service process. And what I would really like is for it to become a permanent element of our construction sites.

Once we finish the tests, the robot will be efficient enough to be used on many construction sites and developed in a completely different direction than today. However, everything will depend on the efficiency that the robot will be able to achieve and the size of the building in which we want to use such machines.

Here, at the hospital construction site in Krakow, we have a small space. The volume that surrounds us on this floor is approximately 500 sq m. If the assumptions included in the project are achieved, this robot would service this room on its own. If we wanted to multiply the effect, we could place four or five such robots here and they would easily cope with the tasks without getting in each other’s way.

Today, the robot can perform several activities. How many missing vacancies can one machine replace?

We are not yet able to provide a precise answer to this question. Everything will depend on the maximum efficiency the robot achieves. Today I would assume that one robot is equivalent to one person on a construction site, but this is a very conservative estimate. I think that we will soon achieve a factor of 1.5 or 2, i.e. one robot will replace two people on the construction site and its efficiency will be the same.

However, this is still ahead of us. We will only make the final decision when we collect all the information after today’s tests, check what they conclude, what else we can get out of this robot, what efficiency it could achieve, and, consequently, how many people can fill the gaps we are experiencing today.

The robot can perform many more tasks. Does the company plan to upload other software to the machine?

That’s the plan. This is the direction after this project that we want to set with our partners, with whom we work together and with whom we work very well, and we have a very positive effect of cooperation between science and business. We want to finish our “Concert” project in the middle of next year. We achieved a much higher level of development of the product we were supposed to create. I think we will still pass one point and be close to the final level of commercialization.

What makes this robot different from others?

This robot is unique because it is mobile. Robots in car factories can do difficult and complicated things, but they do them stationary. Our robot is a mobile platform, and it also moves in difficult environments, where there is a lot of dust, variable humidity and is exposed to falling fragments of debris. He must be immune to it.

Robot is a good solution when it comes to missing vacancies. Construction workers wonder whether a mobile machine will be able to replace a human?

This is not the goal of our project. This robot will not replace a human. I can say this with full responsibility. However, when asked whether robots will one day replace humans, some futurologists say yes. I personally don’t believe in it, or I push away the thought that we will one day be replaced by robots. This robot is designed to cooperate with people and fill these staff shortages. Its premise, as the name suggests, is a robot cooperating with a human.

How much is the rate per hour of robot work?

We don’t know this yet, it’s still ahead of us. An hourly rate is a thing of the future. He is currently on an internship in our company. Today, we have focused on answering the question whether we are able to create such a robot at all, and in a relatively short time we know that we can. The project was initiated in 2021 and was ready in the form it is now in the spring of this year, when it was undergoing laboratory tests. For robotics, that’s pretty fast.

Does the robot need constant human supervision?

The machine still needs constant cooperation with a human, such as uploading a construction project in three dimensions, where after obtaining this data, the robot can precisely perform tasks, e.g. it receives instructions from us: make a series of holes for a steel structure on which facade cladding will later be mounted or paint a room. In this aspect, it still requires human supervision or care, but the robot also has its own battery, which is enough for 8-10 hours of independent work.

After this time, it requires either replacing the battery with a charged one or recharging the battery, so service or human assistance is needed in this respect. However, the ten-hour operating time on one charge is enough to complete one stage or one shift at work.

Foreign exhibitors did not hide their praise for this prototype. You didn’t have any competition at international fairs?

The robot makes us stand out very much. We presented this robot at the robotics fair in Munich, which is one of the largest robotics fairs in the world. And this construction robot of ours was the only robot we met. There were no other proposals that were for construction, especially when they actually came from builders.

We feel very strongly connected to this project, but at the moment it is a virgin area to be developed. Works on construction sites, robots that can move on their own and perform work autonomously – this is a whole area to be developed. I am proud of this project and I think that at the moment we are unique.

Will a mobile machine revolutionize the construction industry in the near future?

This is the goal for these robots to upgrade. Generally speaking, we cannot escape new things. Current forms of work on construction sites mean that construction is not quite the traditional industry as some people perceive it. I absolutely disagree that construction is conservative. This is a very innovative industry and has many modern solutions in terms of both materials and work methods, but robotics is a completely different level. Automation and autonomy are the next level in robotics. Construction using this equipment will be “Next Generation” construction.

The robot will replace employees by taking over difficult and monotonous work. Will his work contribute to greater safety on construction sites?

Many industries will use this form of human support, rather than replacing us, because there are many activities around us that are boring, monotonous and, consequently, have a negative impact on people and work safety. A robot can replace us and free us from such monotonous activities, which in turn will also increase the safety of our construction sites.

Everyone is focused on doing things better, more effectively and safer, but they are also faced with the fact that we as a country have a problem with demography. There are too few of these workers on the market and every company will look for effective solutions to fill vacancies. And this is one of those innovative ideas.